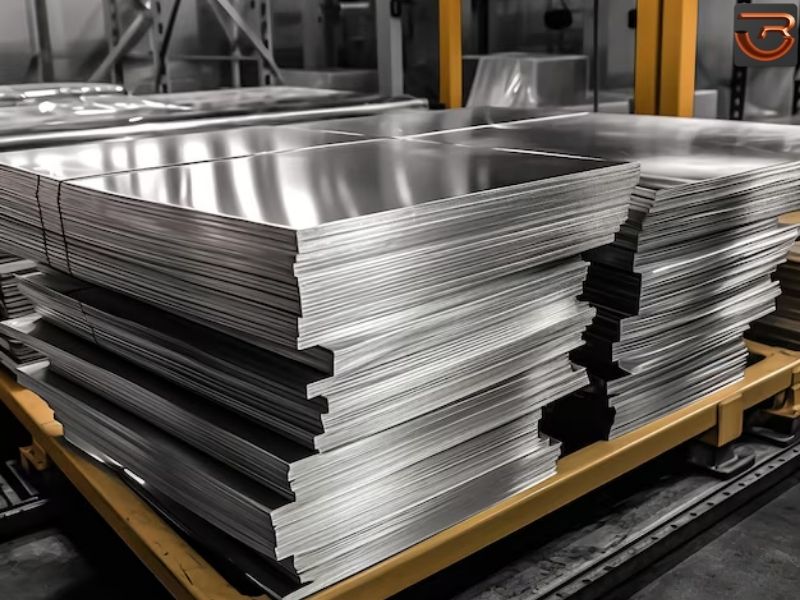

Aluminium stands as a beacon of versatility in modern manufacturing, offering a unique blend of lightweight properties, corrosion resistance, and impressive strength. Central to its adaptability are the diverse alloys, grades, and tempers available, each meticulously engineered to meet specific application requirements. In this comprehensive exploration, we delve into the world of aluminium, uncovering the best alloys, grades, and tempers for a myriad of industries and applications.

Aluminum Alloys, Grades, and Tempers:

- 6061-T6 Aluminum Alloy: Among the most versatile alloys, 6061-T6 combines formidable strength with excellent machinability and weldability. Tempered to T6 condition, it exhibits enhanced tensile strength and resistance to corrosion. Widely utilized in aerospace, automotive, and marine applications, 6061-T6 finds favour in structural components requiring optimal strength-to-weight ratios.

- 5052-H32 Aluminum Alloy: Known for its exceptional formability and corrosion resistance, 5052-H32 is a staple in sheet metal fabrication. Tempered to H32 condition, it strikes a balance between strength and ductility, making it ideal for intricate shapes and designs. Automotive body panels, fuel tanks, and consumer electronics benefit from its versatility.

- 3003-H14 Aluminum Alloy: Celebrated for its high thermal conductivity and resistance to corrosion, 3003-H14 shines in heat exchangers, air conditioning systems, and food packaging. Tempered to H14 condition, it offers sufficient strength and formability for a wide range of applications, from heat sinks to cooking utensils.

- 7075-T651 Aluminum Alloy: The pinnacle of strength and durability, 7075-T651 stands as the alloy of choice for aerospace and defence applications. Tempered to T651 condition, it boasts exceptional tensile strength and stress-corrosion resistance, making it indispensable for critical aircraft structures and high-performance equipment.

- 6063-T5 Aluminum Alloy: Revered for its aesthetic appeal and ease of fabrication, 6063-T5 finds favour in architectural and structural applications. Tempered to T5 condition, it exhibits improved mechanical properties while maintaining excellent extrudability. Window frames, door frames, and curtain walls benefit from its corrosion resistance and visual appeal.

Best Applications for Aluminum Alloys and Tempers:

- Aerospace: 7075-T651 and 6061-T6 alloys stand at the forefront of aerospace innovation, offering unparalleled strength and durability. Tempered to optimal conditions, these alloys ensure optimal performance and reliability in the demanding aerospace environment, from aircraft frames to engine components.

- Automotive: In the automotive sector, 5052-H32 and 6061-T6 alloys play pivotal roles in enhancing fuel efficiency and vehicle performance. Tempered to H32 and T6 conditions, respectively, these alloys contribute to lightweight body panels, precision-engineered components, and structural reinforcements without compromising safety or durability.

- Marine: 5083-H32 and 6061-T6 alloys navigate the harsh marine environment with resilience and longevity. Tempered to H32 and T6 conditions, these alloys offer superior corrosion resistance and structural integrity, making them ideal for boat hulls, offshore platforms, and marine components subjected to saltwater exposure.

- Construction: 6063-T5 alloy adds a touch of elegance to architectural designs, combining aesthetic appeal with structural integrity. Tempered to T5 condition, this alloy lends itself to window frames, door frames, and curtain walls, enhancing the visual appeal and functionality of modern buildings while withstanding the rigours of weather and time.

Aluminum's versatility knows no bounds, thanks to the myriad alloys, grades, and tempers available to meet the diverse needs of industries worldwide. By selecting the suitable alloy and temper for each application, manufacturers can harness aluminium's full potential, unlocking new possibilities in the aerospace, automotive, marine, and architectural sectors. As we continue to innovate and refine aluminium alloys, the future holds promise for even more incredible advancements, driving progress and sustainability across various industries.

Best Price Aluminium 6082 T651 Plates | Aluminium 6060 Round Bar Supplier | Best Quality Aluminium 6061 T651 Sheets | Versatile Aluminium Bars & Rods | 5086 Aluminium Plates Strength & Versatility | Aluminium 6061 Sheets Stockist | Reliable Aluminium 6082 Plate | Top Aluminium Supplier: Renaissance | Aluminium 6061 Round Bar Supplier | Explore Aluminium 6061, 5083, 7075 Sheets | Aluminium Alloys & Tempers Guide | Aluminium Bars & Rods Key Grades | The Lightweight Wonder Aluminium | Aluminium Alloy Selection Tips | Cost-Effective Aluminium Products | Endless Possibilities Aluminium

Comments

Post a Comment